It’s natural to have concerns about which rope to use for different applications on your boat. At V.elo, we understand this and want to help you make informed decisions that will help you achieve your sailing goals.

One crucial factor to consider when selecting ropes is the core material, and the most popular options are polyester, Spectra®, and Dyneema®. Each material has specific benefits for each application, but how do you know which option is best for your boat?

First and foremost, safety is paramount when it comes to selecting ropes. Whether you’re using them for leisure or performance, onboard safety is non-negotiable. Therefore, it’s essential to understand the differences between the materials and choose ropes that are durable and can provide total safety

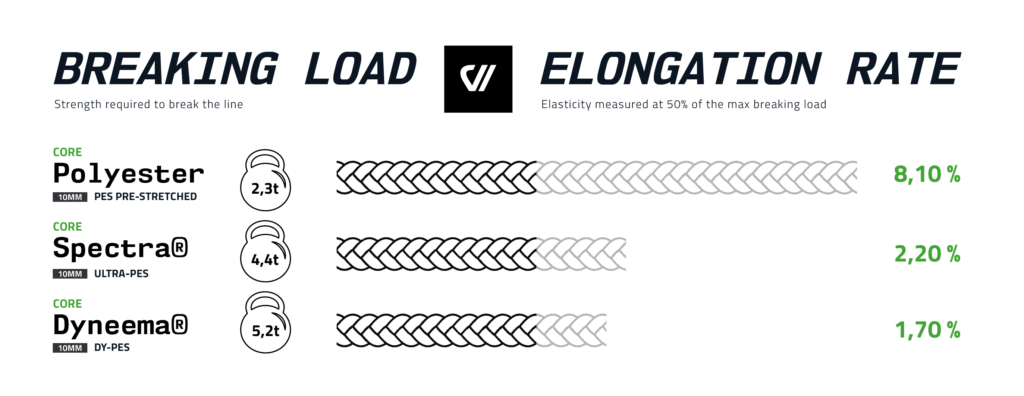

When it comes to double braid ropes (with a core and an outer cover), two essential characteristics to analyze are max breaking load and elongation rate

Breaking load refers to a rope’s strength, indicating the load required to break the rope under tension. The average working load of a rope should be between 25 and 30% of its breaking load, and it’s crucial to select the right ropes according to the load of each function to conserve the durability of both the material and the hardware and equipment on the boat.

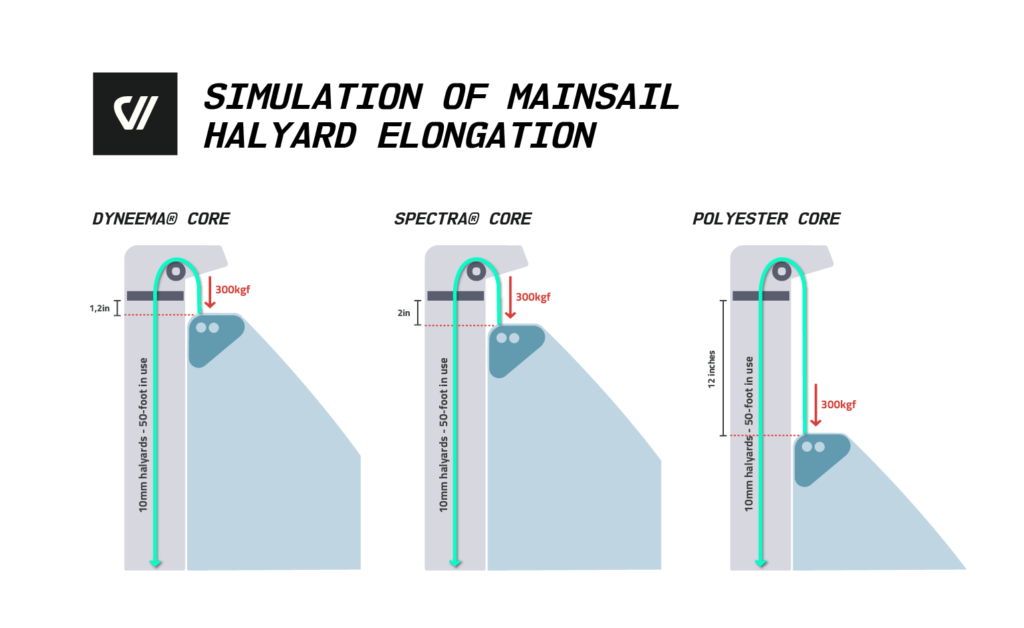

Elongation refers to a rope’s elasticity or how much it stretches and elongates under load. The elasticity of a rope should consider the objective of its application. For example, elongation can be useful in mooring ropes, which absorb the impact of the boat’s sway on the pier. However, in cases such as halyards, elasticity is a negative characteristic that causes the rope to “succumb” during use, affecting the height and shape of the sail.

The elongation rate is measured by applying 50% of the rope’s breaking load since the most common working load in racing or leisure boats is about 25 to 30%, and therefore does not exceed 50% even in more extreme uses.

The material chosen for the core of your rope is directly related to the function that the rope will perform on the boat. Polyester (Pre-stretched PES), Dyneema® (Dy-PES), and Spectra® (Ultra-PES) are the three most common core types.

You can find ropes with all three types of cores in V.elo’s digital catalog.

Polyester Core Ropes:

ideal for dinghies, small sailboats, and cruising boats.

Polyester ropes are the most versatile on the market, with applications ranging from mooring to sheets and halyards. They are strong, very resistant to abrasion, heat, and UV rays.

For smaller and one-of-a-kind boats, as well as those used for cruising and touring, ropes with a polyester core are a top choice, providing both exceptional quality and affordability. The outstanding features of these ropes are their superior durability and softness, making them highly recommended for high-use applications such as sheeting and controls.

However, it’s worth noting that the polyester core presents greater elongation and lower breaking load than the HMPE options, which makes them less suitable for applications with very high loads or extreme precision.

Polyester core ropes typically have an elongation rate of around 8%. This means a 32 feet line working at 50% of its breaking load would elongate by 30 inches.

Although, it’s important to keep in mind that cables typically don’t work with such a heavy load. For example, a 10mm diameter PES would need to work with over 1 ton of weight to reach 50% of its breaking load. Nevertheless, even a halyard giving way by 4 to 8 inches could make a significant difference in the shape of a sail.

Spectra ® Core Ropes

Ideal for Monohulls and Sailboats Over 30 Feet

For cruising boats over 30 feet, we recommend using Ultra-PES, a variation of the V.elo cruising line, with a Spectra® core. The Spectra® core essentially doubles the max breaking load of the rope, with the elongation rate dropping to just 2.2%.

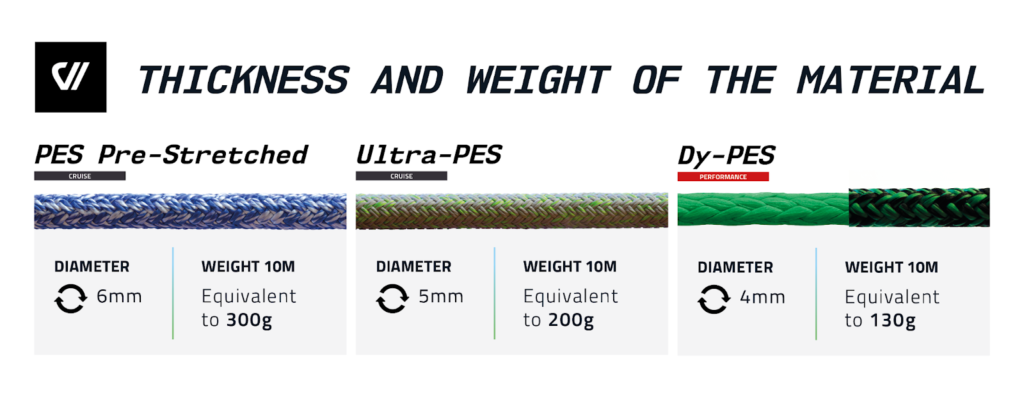

In addition to greater onboard safety, the use of Ultra-PES allows the use of smaller diameters, reducing the total weight of the material and the effort of the entire system. It is a more suitable option for these applications, also increasing the durability of the rope.

As the Ultra-PES does not have a coating (protective resin) added to the core strands, it is not suitable for applications where the core will be exposed and pulled out of the cover. In these cases, Dyneema® cores are the best option.

Dyneema ® Core Ropes

ideal for high-performance racing boats

Dyneema® core ropes are the go-to choice for high-performance racing boats where precise sail trimming and adjustment is crucial.

For optimal results, we recommend selecting from the Dy-PES and Dy-Tech line, which offer a variety of Dyneema® core options.

Dyneema® is the leading brand of HMPE (High Modulus Polyethylene) fibers on the market. It is an incredibly strong and lightweight material with a high breaking load and virtually no elongation. To put it in perspective, Dyneema® can be 10-15 times stronger than steel if compared to the same weight of material.

These characteristics make Dyneema® core ropes the primary option for high-performance boats and larger sailboats, as they not only provide reliability but also allow for the use of smaller diameters ropes and even bare applications, which significantly reduce the overall weight of the boat.

The Dyneema® core’s extremely low elongation rate of 1.7%, combined with its high max breaking load, offers incredible precision in sail trimming and adjustment. Halyards and sheets that do not yield to the wind’s force or gusts ensure that the sails maintain their shape and power curve in the right place.

The lightness and strength of Dyneema® core ropes are also specific advantages for spinnaker sheets. In addition to resisting the wind’s high loads on a run, the Dyneema® core can be used exposed at the ends of the sheets, reducing the weight of the ropes significantly. This is essential not to interfere with the spinnaker in light winds.

This is made possible by applying a protective coating, which can be done in different colors and adds significant protection against UV exposure and especially the abrasion from direct contact with surfaces such as blocks, eyes, and other onboard fittings.

As its fiber is incredibly smooth, the exposed Dyneema® core is also excellent for facilitating maneuvers and sail changes with less friction and for sliding through the various rope control systems. For the same reason, it is not recommended to use it directly without adequate covering in high-abrasion and grip applications, such as clutches, jammers, and stoppers.

With such a significant difference in load and elongation, choosing the correct material for each application is crucial. Let’s take, for example, a 30-foot boat with a 40 feet mast and a 50-foot halyard in use, from the top of the sail to the stopper. With the mainsail working on average with 300 kgf, the elongation of a 10mm halyard with a polyester core can reach up to 12 inches, compared to just 2in with a Spectra® core and a minimum of 1,2in with the Dyneema® core rope.

Pretty impressive, isn’t it? To gain a deeper understanding of the distinct applications of each rope and optimize its performance, safety, and maintenance aboard your boat, do sign up for our newsletter.

Always remember: it’s important to know the boat and the context to make the ideal choice.